LEADERS IN QUALITY INJECTION MOULDED PLASTIC COMPONENTS & PRODUCTS

SERVICES

ABOUT

Metplas is an Australian family owned and operated manufacturer of injection moulded medical, electrical, marine, technical and startup plastic components and products, with over 40 years experience.

-

We have 6 fully automated injection moulding machines with sprue pickers to guarantee efficiency and reduce production costs.

-

2 of our Engel machines are within a Class D Accredited clean room to ensure a clean, hygienic environment.

-

Our computer monitoring of machine performance and production rates ensures accuracy, efficiency and quality.

-

Our operations are based on quality standards ISO9001

-

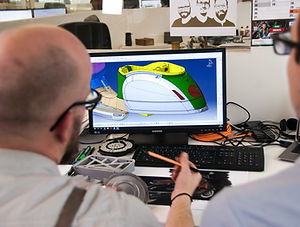

We help turn ideas into innovative product designs using 3D computer modelling, prototyping and mould design and tooling.

-

We are nimble - our lead times are short and we respond to orders efficiently.

PROCESS

Idea

Design

Material

Mould

Testing

Production

Come to us with your concept, sketch or CAD drawing.

Design and develop your idea into a workable product. Then prototype and perfect.

Select and evaluate suitable materials and additives.

Design tooling to ensure consistency of product, and minimisation of waste.

Test and evaluate the mould and make any adjustments as required.

Begin production, package and deliver finished product.

MATERIALS

Metplas has experience manufacturing with an extensive range of materials from Polyolefin to Engineering Polymers to Recycled Polymers. We can also incorporate various pigments, slip additives, UV stabilisers, anti-microbial, scent, luminescent and glitter additives into the base polymer.

QUALITY

Quality is of paramount importance to Metplas, and substandard production is simply not an option. We take pride in every product or component that leaves our factory, which is why our operations are based on the international standards for quality – ISO9001.

This means having processes to check the quality of our product at key moments in the production cycle. It means retaining and checking samples; material, production and product traceability and a safe and clean working environment.

TESTIMONIALS

What our clients say about us.

Stayput Fasteners

Metplas has been manufacturing our products for 3 generations spanning 50 years. In that time we have successfully designed and launched over 25 products, our most recent product having just won an innovation award. We strive to produce consistently high quality parts and Metplas never let us down. Their fast turn-around also allows us to manage our stock holding efficiently and ensure we never run out of stock. Our long partnership with Metplas has been an integral part of our success and growth.

ENVIRONMENTAL STATEMENT

Metplas are passionate about sustainability throughout the manufacturing process. We continually strive to reduce our environmental impact by:

-

Using solar to power 1/3 of our energy requirements

-

Creating moulds that minimise, or even eliminate, waste material in the production process

-

Using raw materials efficiently

-

Researching, trialling and implementing alternate materials including bio, recycled and ocean plastics

-

Reducing office and factory waste

CONTACT

Contact Us

Call +61 2 9982 2488 or complete the form below:

Head Office

Unit 9, 93-99 South Creek Road,

Dee Why, NSW 2099 AUSTRALIA

ABN: 46 104 468 091

Tel: +61 2 9982 2488

Have an idea for a product, or want to find an Australian manufacturer? Call us today +61 2 9982 2488